The N-888-HV Series Dispensers were designed and developed to precisely and reliably dispense High Viscosity (1-2 Million CPS) One Part Urethane Adhesives. Some models of these Heavy Duty Workhorses have dispensed as much as 78.5 in3 of HV Urethane per stroke. Others have dispensed at flow rates as high as 250 in3/min and some have satisfied production rates as high as 90 jobs per hour.

All N-888-HV Series Dispensers are Positive Displacement Single Acting Lance Piston Meter Dispensers with Power Flow Valves on the Inlet and Outlet of the Metering Cylinder. Meter capacities available range from 9.8 to 78.5 in3 per stroke, with the standard being 49 in3.

The standard N-888-HV unit pictured above with the optional –ROB and Casters options is a Heavy Duty Hydraulic powered dispenser with precise flow control provided by its 2 selectable key lock Temperature and Pressure Compensated Flow Controls on its Hydraulic Power Unit. This system has a maximum flow rate capability of 150 in3/min. It can dispense at pressures as high as 6000 psi material pressure and only require 1500 psi hydraulic pressure to do it.

The “–ROB” Option, available for any of the N-888-HV Series Dispensers, includes a Volume and Flow Rate Indicator with High and Low Alarm Set Points as well as Pin Receptacles for interfacing the dispenser to a Robot or other Supervisory controller.

The N-888-HV-TF-ROB Series dispenser pictured above is another version of the N-888-HV Series dispensers. The “–TF” suffix stands for Twin Flow dispenser. These systems have 2 Metering Units with common Inlet and Outlet plumbing, a common Hydraulic Power Unit and additional control functionality. They are used in High Duty Cycle applications where One metering unit Dispenses while the Other metering unit Refills. In this manner, the system is always ready to dispense. There is no need to wait for Refill to complete before the next dispense cycle can start. The twin meters also provide a measure of “back-up” to the dispensing cell. If one metering unit were to malfunction, the other can continue cycling.

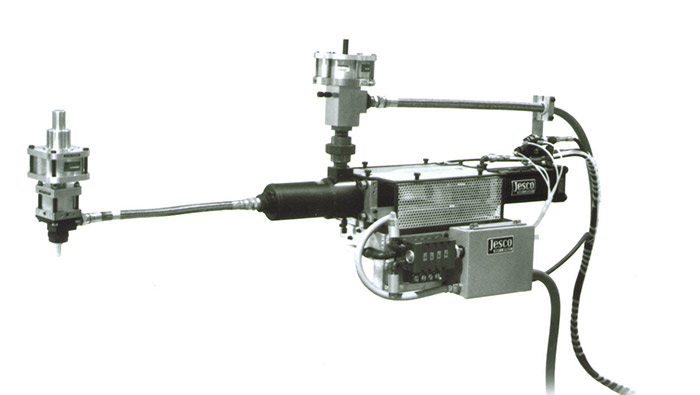

The N-888-HV-AH-LRM Series dispenser pictured above represents yet another variation in the N-888-HV Series. The “-AH” suffix stands for Analog Hydraulic dispenser. This feature allows the Robot to set the dispensing flow rate by sending an analog signal to the dispenser. The dispenser responds to this signal and dispenses at a flow rate that is proportional to this signal with full compensation for variable loads.

The “-LRM” suffix stands for Lightweight Robot Mount dispenser. This version of the N-888-HV Series dispensers is designed to allow the metering unit to be mounted on the arm of a Robot. By mounting it close to the dispense tip, dispensing pressures are lower and changes in the commanded flow rate by the Robot can be realized at the tip with less delay. The entire metering unit assembly for this dispenser weighs 200 lbs. It is capable of dispensing at up to 4000 psi and can deliver up to 39.2 in3 of material per stroke.

The N-888-HV-AE-TF-ROB Series dispenser pictured above is yet another variation in the N-888-HV Series of dispensers. The “-AE” suffix stands for Analog Electric dispenser. These systems are entirely electric powered and include Heavy Duty 240 in-lb Continuous Torque DC Servo motors driving High Duty Cycle 20 ton Ball Screw Actuators. These systems also allow the Robot to set the dispensing flow rate by sending an analog signal that is proportionate to the flow rate required.