The N-3200-GP Series FACTS Dispensers are but one of several different types of Full Analog Control Tracking Systems available from Jesco. These systems are used in demanding applications requiring very precise bead size control and consistency and where Robot cycle times need to be minimized.

This Patented Dispensing System allows the Robot to place a constant sized bead of material on any part while it varies the speed of the dispense tip, or if required, vary the bead size at any point in its path independent of the Robot Tip Speed. The FACTS system does this by responding instantaneously to an analog signal from the Robot that is proportional to the Instantaneous Flow Rate of material required at any point in the Robot’s path.

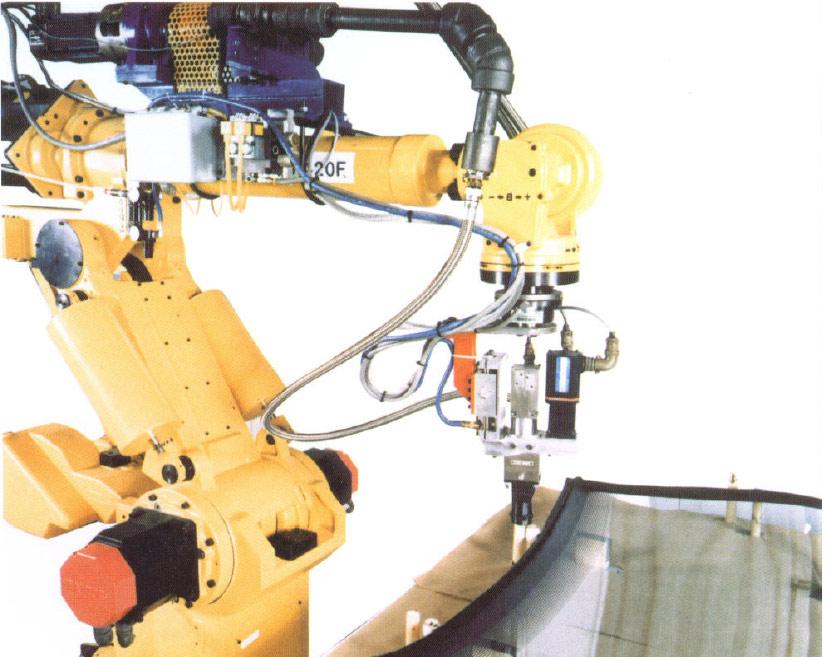

The FACTS system pictured includes an Electric Servo Driven High Viscosity Gear Meter Unit and an N-2995 Analog Electric Flow Gun. This type of system is typically used on Automotive Glass Bonding Applications where the Robot moves the dispense tip around the glass (stationary glass). The FACTS system dispenses the perfectly consistent bead of urethane required all around the glass, while the Robot varies the tip speed through corners and along straight-a-ways in order to minimize cycle time.

The FACTS technology is not limited to the use of one type of metering unit. FACTS systems can utilize any Hydraulic, Air or Electric Servo Driven Positive Displacement Metering Unit as the metering device. Coupled with one of Jesco’s 2 Analog Electric Flow Guns available, a FACTS control panel and a PPCP package (proportional pressure control package) for the supply pumps, there is a FACTS system available for nearly any dispensing application.